A New Challenge

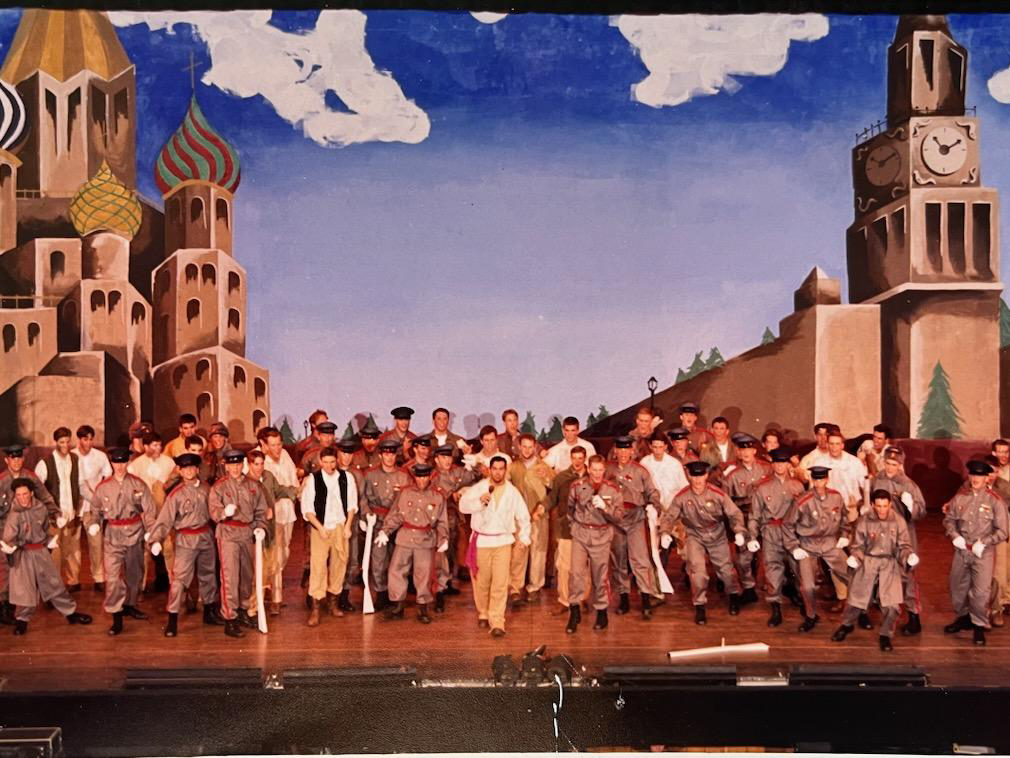

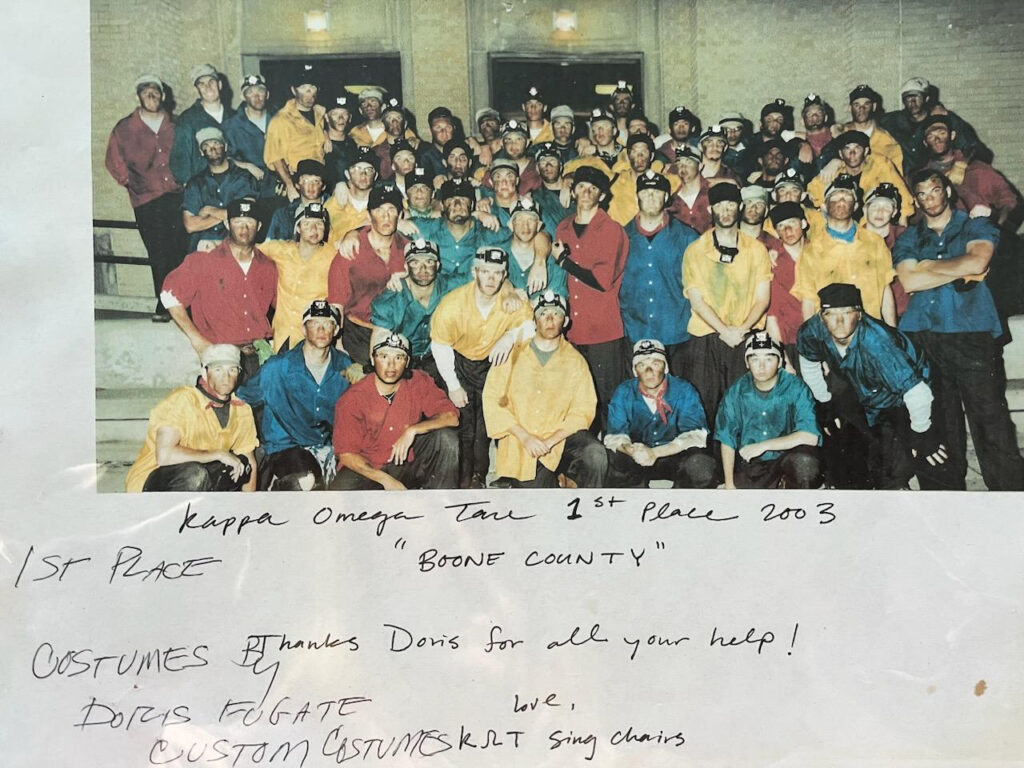

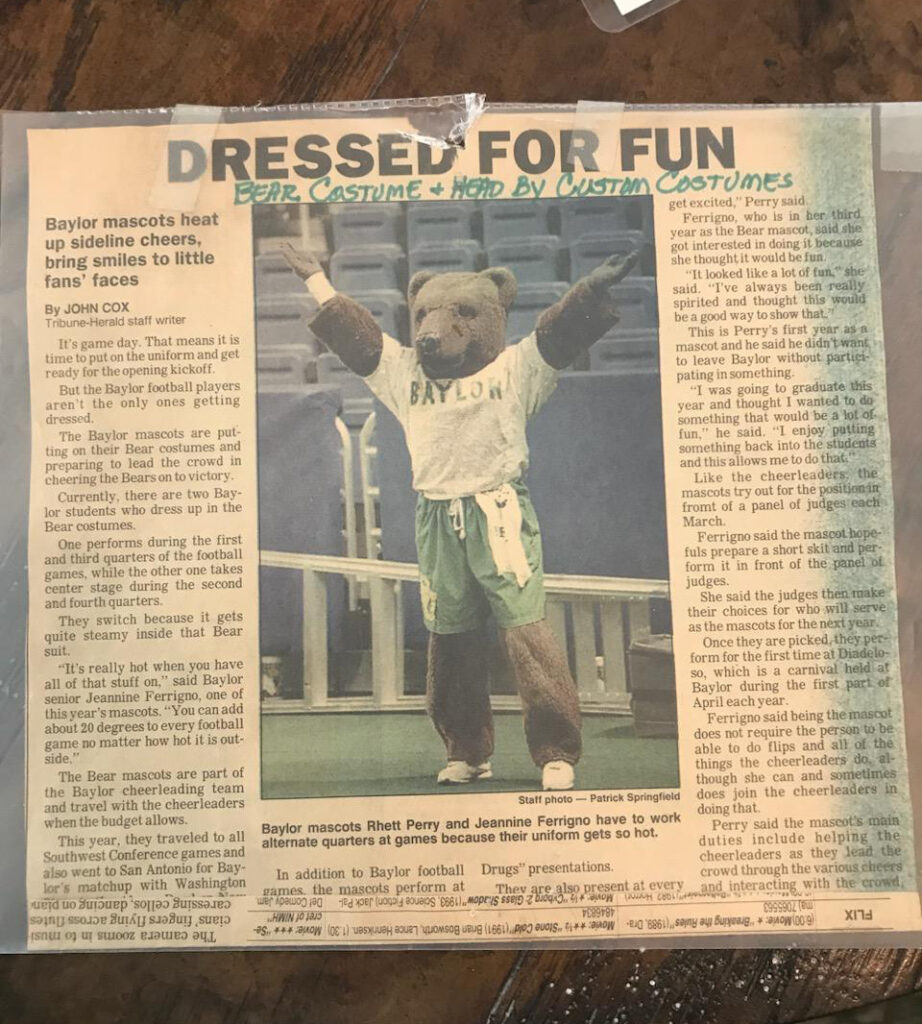

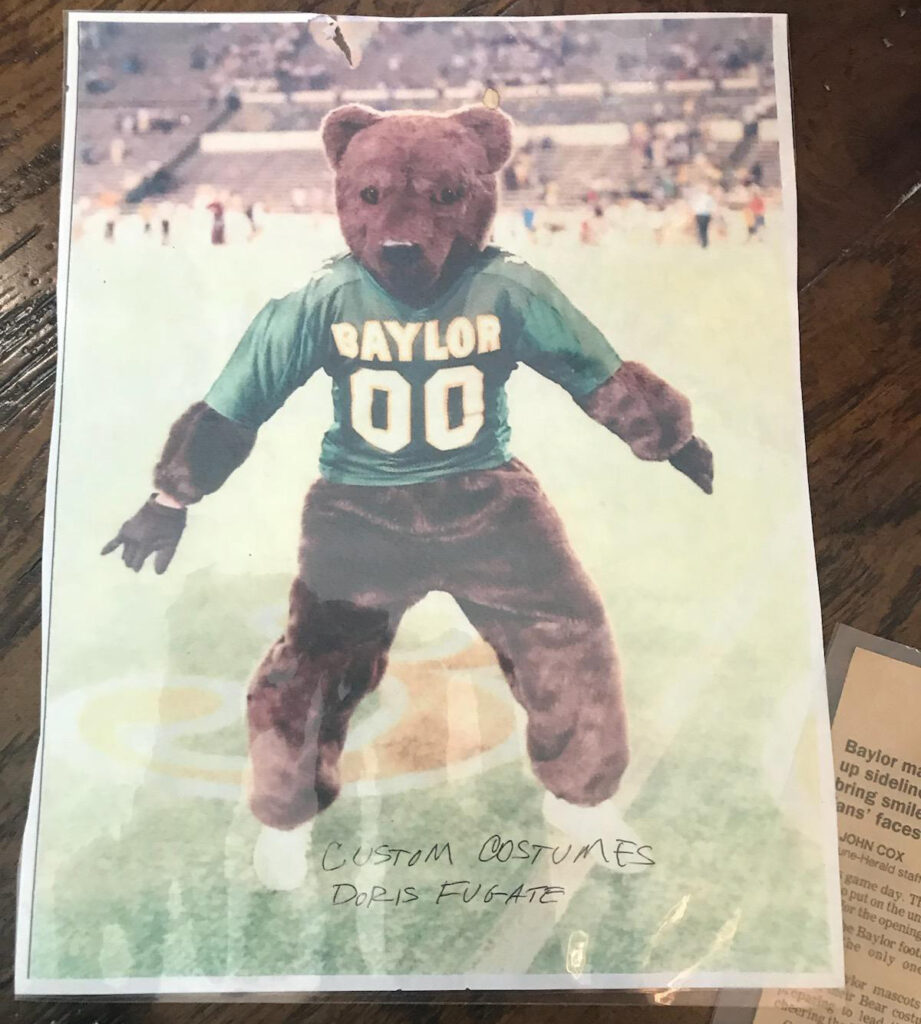

The Sororities and Fraternities of Baylor found her work to be quite impressive. Year after year Doris designed and produced hundreds of costumes for Sing. It’s no surprise that the higher-ups at the University started to take notice. Recognizing her ability to create and sew, Baylor decided to offer her a chance to create their first ever mascot, Bruiser the Bear. (Technically he was known as “man-in-bear-suit” at the time according to Baylor’s blog, the name Bruiser didn’t come till later)

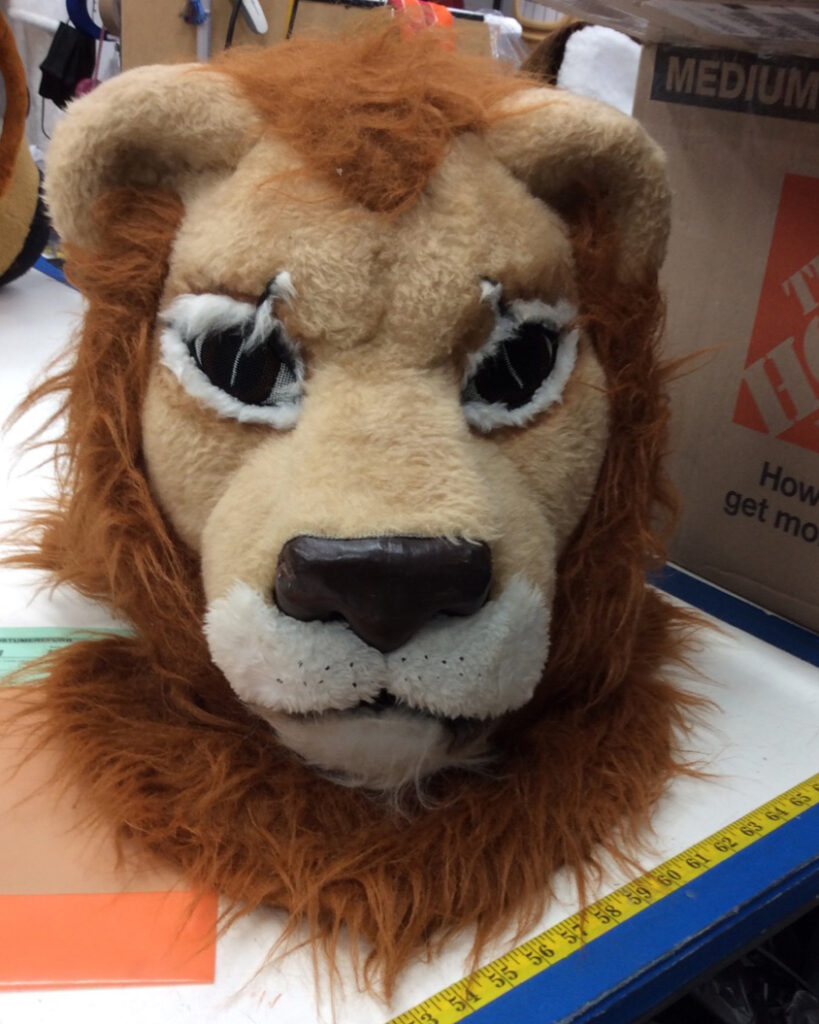

A mascot involves plastic molding, interior rigging, and weight management; a challenge that Doris had yet to encounter in the costume world. Nevertheless, she set to work. The body itself was pretty easy, as it was just a furry suit. The head however, was quite a bit more challenging. Mascot heads are typically made of ABS plastic and often require a harness to support their weight. Being that Doris didn’t exactly have any plastic thermoforming equipment, she opted instead to outsource the molding process to a dedicated mascot company. After finishing the mold the company sent it to her, she would then begin the process of covering it with fur to match the suit.

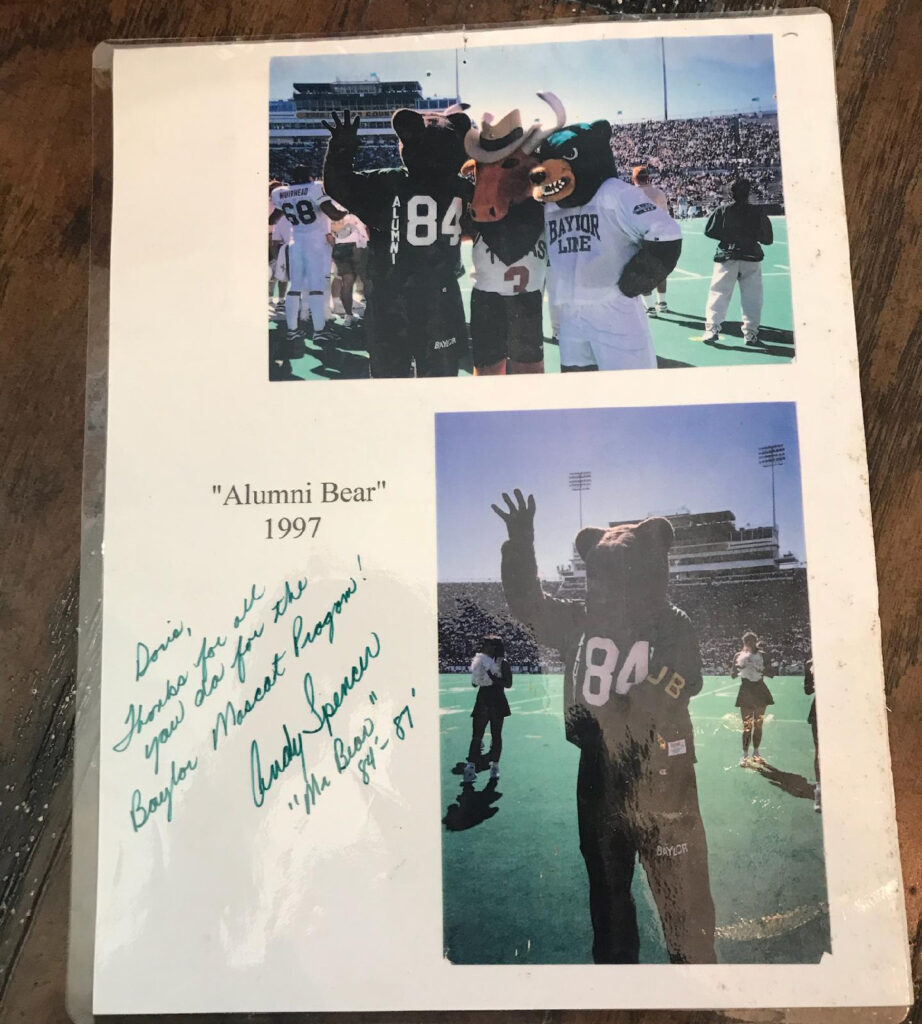

News of Doris’ achievement spread, and soon she found herself working on mascots from several other Universities. Eventually her company started expanding their business by offering mascot costume rentals, cleaning services, and repair work. Paul headed up the mascot repair division. His experience running a drilling company and building airplanes managed to translate into mascot repair. His workshop was conveniently right next to the farmhouse, and anytime his wife needed some help, he cleared his desk of P-40 airplane parts and broke out the dremel!